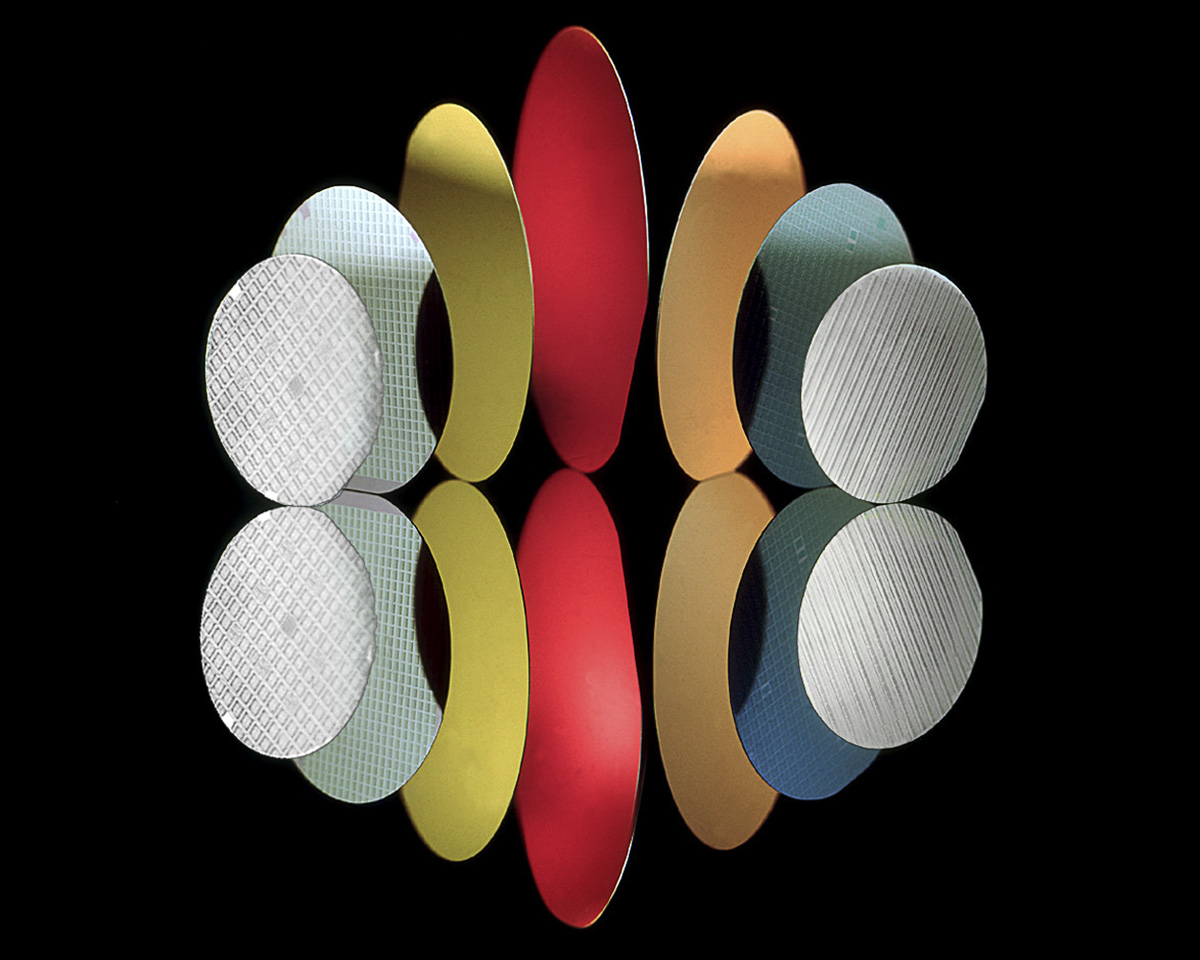

Back In The Day Commercial Silicon Wafer Photoshoot

Posted on November 4, 2021

I was going through old backup drives and found this image of Silicon Computer Wafers I shot for a brochure cover for one of my Hi-Tech Commercial Clients . This was shot before Digital Cameras were around with a Sinar 4×5 View Camera with a Caltar 210mm lens with Kodak Ektachrome 64 Transparency film. Than we processed the film in-house & scanned the film @2400 dpi to deliver a 4×5 Transparency & a Digital file for the client. This was setup & shot on a Glossy 4×6 ft sheet of P95 Black Plexiglass. We taped a nail to the back of each Silicon Wafer and drilled a small hole in the Plexi to put the nail through to angle the Wafers where we wanted them for the setup & reflections. The colorful wafers then nicely reflected on the glossy black plexiglass sheet giving a mirrored Reflection of the wafers. The next step was to position a Speedotron Flash Head with a “snoot” attachment to light each wafer separately. On the ones I wanted a color added to the wafers I taped a colored “gel” (Plastic colored acetate to add color on that wafer). I have to say Digital Photography would have made this a Whole Lot Easier! But there again it made you solve problems & come up with ideas to get the Final Image that was needed for the Client!

Category: Abstracts, Blog, Commercial Photo Shoot, Equipment, Favorite Locations, Product Photography, Studio, Studio Tagged: 4x5 Sinar Camera, Caltar 210mm View Camera lens, Commercial Photo Shoot, E6 Film Processing, Ektachrome 64 4x5 film, P95 Plastic Sheet, Silicon Wafers, Speedotron 102 Flash Heads, Speedotron Black Line strobes, Speedotron Black Line Studio Flash Power Supply, studio photography

photoartflight

photoartflight